Who Makes Darn Tough Socks?

We get asked a lot about Mill tours. We don't currently have them, but if you've ever wondered who makes Darn Tough socks and what our process is, we did want to give you an inside look.

A lot goes into making the best sock. You need the right materials, right knit, right pattern. Most importantly though, you need the right people. It’s the “who” behind every aspect of our sock knitting process that makes us so confident in their quality, we choose to guarantee them for life.

Let us introduce you to the people who make Darn Tough socks (if you didn't know already, these are socks made in USA with yarns sourced from America and around the world). You might learn a bit about sock-making along the way.

Owen — Product Line Manager

Owen’s been at Darn Tough since 2016. When he’s not thru hiking the AT or playing classical viola (harder than it sounds since not many composers choose the viola as their hero instrument), he’s at the Mill in Northfield, VT working with our research and development (that’s R&D) team.

R&D is where the sock journey begins. Owen and the product team are always researching. He then uses this research to make recommendations, thinking seasons and even years into the future.

What new socks should we make next? What changes should we make to our current socks to make them that much better? What colors should be using? These are all questions Owen and the other R&D team members help answer. (If this is part's exciting to you, learn more about how we design socks.)

“I think it’s a great balance of analytics and creativity,” says Owen. “We’re constantly asking ‘why’ and the answer to ‘why’ needs to account for both.” Our socks can’t just look good, they need to be functional and meet the needs of sock-wearers everywhere. It doesn’t hurt if they look good, too.

Once R&D feels the vision for socks coming together with some solid designs and styles, we have to turn that design into something our knitting machines can understand. Not every idea will make it past this first knit down, because what works on a computer doesn’t always work in real life (at least, not the way you think it will).

Among elements that can go wrong, Owen names color, pattern, and of course fit. “We never launch a new style without wearing it. Wear, wear, wear. Wash, wear again.”

To find out just how the sock is going to look and fit in real life, Owen and his team hand their sock ideas over to the Samples Group.

Before we leave Owen though, just gotta mention he’s one of the honored few to have a sock named after him. VanGrizzle isn’t just an awesome sock with a bear on it… it’s also his trail name. No wonder it’s Owen’s favorite design.

Clay — Samples Programmer

With 11 years under his belt, Clay knows a few things about brook fishing (one of his favorite activities) and sock making. By a few, we mean he can walk you through the entire process from sock bitmap to knitting machine functions. And he’ll do it with a smile, answering all your questions along the way.

When R&D sends the Samples Group their idea, Clay asks, how do we make this idea real using the tools we have? He turns that idea into a bitmap (looks like a virtual paint-by-number, actually is a super complex guide for every single stitch in a sock, dictating the color, material, and other details like cushion).

But not having the right tools or program doesn’t stop Clay. R&D wanted to make socks with a striped heel and toe, something we’d never done before, so Clay built the program from scratch.

This pioneering is what he loves about his job. “Doing things that nobody else wants to do. That’s what our team does.” If you love all the stripes covering the Animal Haus socks, don’t forget to thank Clay for saying “I’ll try it.”

With the bitmap done, Clay and the Samples Group puts the sock pattern into a program and knits a real-life sample on one of our knitting machines.

They watch out for red flags at every step, passing that information back along to R&D to make tweaks as needed. R&D spends days and months wearing the samples, making sure they live up to the Darn Tough standard of uncompromised comfort, durability, and fit.

Thanks to Clay and his team, problems are caught early and fixed, or the sock is scrapped. Not every awesome idea makes it through to production (though many do).

Don — Purchasing Manager

Once a new sock has made it through the process we can say, yes, we are making this sock. That’s when Don and his team step in. Don’s been the purchasing manager at Darn Tough for 4.5 years now, and his job is to find the best materials and get them from wherever they are in the world to our Mill in Northfield, VT. No easy task.

When asked what he loves about his job, Don had a couple answers. First, he loves working with our supply partners and maintaining those relationships. But he also just loves Darn Tough:

“What I like is the product and the people. I’ve worked in manufacturing for a long time. I love working for a manufacturer that makes the quality of product I can stand behind and use in my daily life being a mountain biker, runner, snowboarder, and hiker.”

He still has the socks he wore to hike Machu Picchu in Peru, and every time he sees them, they remind him of that hike. “We make such a kick-ass product.”

We can’t make a great product without great building blocks. Don and his team make sure the Mill has the yarn they need, when they need it, and with the highest possible quality. They also help R&D look into new materials, seeing if they’re up to par with our quality standards. The glow-in-the-dark nylon didn’t make the cut (sad day, we know), but the space-dyed yarn did.

Don is also helping us as a company to take better care of the environment with sustainable materials. In recent years, that meant finding and changing all our Merino Wool yarns to 100% Responsible Wool Standard certified wool.

Now, he’s repeating the process for our nylon yarns. Every day, he and his team are matching colors for recycled nylon, with the goal of moving 100% of our yarns to sustainable options.

The COVID19 pandemic slowed the process as supply chains around the world felt the impact, but they haven’t stopped, and Don is proud of the work his team has done and continues to do to source the highest quality materials.

Michael — Line Supervisor

Aka Big Mike. This dude is tall. And despite his British accent, he has a love for Vermont that is unsurpassed. After a few years at Darn Tough, he headed off to Florida only to find his way back to Vermont and the Mill. He’s been here 5 years now, grooming dogs when he’s not keeping an eye on the Mill.

Mike is the first shift supervisor at the Mill, overseeing all our knitters and knitting machines. To get all our socks out the door in the right sizes, colors, and quantities takes a lot of scheduling. Mike manages that schedule, no small task when you consider our goal of knitting over 60,000 socks per day. Yes, per day. You all wear a lot of socks.

With the program from Samples and the materials from Purchasing, socks are ready to be knit on a large scale. Knitting is the very heart of the sock-making process. Knitters are responsible for keeping the machines stocked with the right yarns, including making a list of the yarn they’ll need for each day to complete the scheduled work.

Knitters also keep an eye out for issues – a broken needle or thread makes an unacceptable sock. Knitters hand-inspect socks at the machine to catch these issues and correct them in real-time, while also making sure that the socks leaving the knitting room are top notch.

Each sock has its own personality, which can come out in the knitting process. “The 1466 runs like a peach,” per Mike, but a new sock might not, challenging Mike and his team to spot and troubleshoot issues. Mike’s favorite thing about his job is working in a fast-paced environment where he gets to know people, how they work, and help them work even better by passing along his knowledge.

Adnan — Master Technician

Sometimes a knitting machine has an issue that’s more complicated or too difficult for the knitter to fix. That’s when it’s time to call in a technician.

With an impressive 23 years at Darn Tough, Adnan is what we call a Master Technician. There’s not much this man doesn’t know about our knitting machines. A knowledge he’s happy to humbly share, while having some fun too. “I’ve been here 23 years, and I’m still learning.”

One of his favorite parts of work is having fun with his coworkers. “I try to treat everyone with respect and a little fun.” When not at work, he enjoys spending time outdoors with his family. At home or at work, there’s a high likelihood he’ll be wearing his favorite sock, the Light Hiker Micro Crew.

When it comes to fixing the knitting machines, Adnan encourages the technicians he’s training to look for the simple solutions first. With over 270 knitting machines to keep up and running, every day presents its own unique challenges, and he’s always looking to help others improve their skills and expand his own.

When new socks are coming into the Mill, Adnan sets up the program on the machine, double-checking that all looks good, and does a small pre-production run of the socks before moving the socks along to full-scale production. If any issues come up, he takes them back to the Samples Group and works with Clay to find out where the problem is – with the machine, the program, or the material.

The problem-solving never stops, and every person at every step of the sock-making process are committed to making only the best socks, something Adnan takes pride in.

“What we want to make is the best in the world, and we are.”

Follow on Down the Road

We've covered a lot, but the sock-making process is far from done, and we have a few more people we'd like you to meet. What happens next takes place down the road at our Nantanna building (the name means "fine spinner"), which is nestled between Northfield's Main Street and the Dog River.

Dylan – Boarding Supervisor

After the socks are knit, we clean them for you. No need to fear that first time throwing them in the laundry (though you might want to check out our sock washing instructions). This isn’t their first rodeo – Dylan and his team have already put them through the wringer (figuratively anyway).

Dylan walks into a room with a big smile under a mop of curly hair. He’s just that kind of guy. The kind of guy who loves spending free time hiking with his one-year-old husky pup.

With seven and half years of Darn Tough under his belt, Dylan has seen a lot of Darn Tough’s growth, including process improvement. When he first started, all washing and drying happened at our Mill in Northfield, and it took 40-50 minutes per load. He’s happy to report how that’s changed saying, “It’s much more efficient; we’re tuning everything up.”

Today, socks leave the Mill after being knit, and travel via truck about 5 minutes down the road to our Nantanna building. The large bags of socks come off the truck and go straight to the Wash/Dry team.

With upgraded laundry machines that are both a washer and dryer in one, the longest a load takes these days is 11 minutes. Each machine contains programs for the different sock styles and thicknesses, ensuring a perfect first wash.

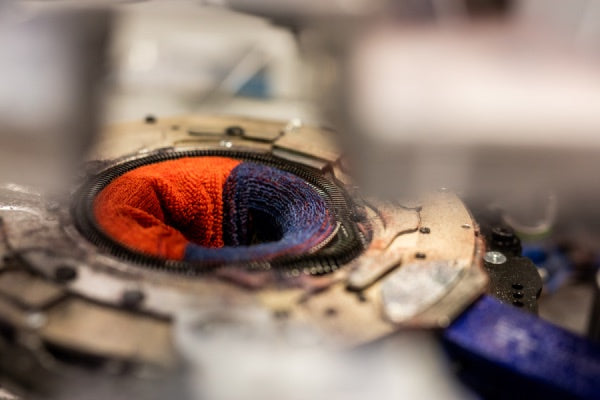

Once the socks come out all dry and fresh smelling, they go to Boarding. Think of this as ironing in the air. Each sock gets hand placed onto a metal sock form. The forms are by size: large socks go on large forms, small socks go on small forms, etc. These forms then travel through some super hot air. Boarding makes sure the sock is the right size and shape, ready to wear.

“It seems like an easy job,” Dylan explains. “A lot of people walk through saying, it’s just throwing socks on a form. It actually takes skill to make the sock come out looking good. I think it’s a talent, and it’s hard work. The machines run at 300 degrees, and it’s so hot.”

Despite the heat, Dylan loves his job. “It’s a good vibe here. The team camaraderie and moral are like something I’ve never seen.” It’s not unusual for the team to meet up for post-work basketball games.

Beyond forming the sock, Boarding is a moment when every single sock gets touched. As boarders place the socks on the forms, they handle every sock, making sure to catch any irregularities and flag them with a red tag. This red tag is a signal to Auditing that this lot of socks warrants a closer look.

Heather — Inspecting Technician

“I’m maybe a little OCD. Just a smidge.”

If you’re auditing socks, being a little OCD can serve you well. Heather has 6 years of quality inspection experience. If there’s something wrong with a sock, she’ll spot it. And she might be listening to heavy metal at the time (“People don’t expect that. Yes, I’m old, but I love heavy metal.”)

After a sock has been boarded, it gets placed with the rest of the socks from its lot onto a rolling cart and sent over to Auditing for inspection. About 20% of a day’s socks get hand inspected right then. The team also notes any red tags and goes through every sock from that lot to make sure the socks are meeting the rigorous quality standards.

This isn’t the first or last time a sock gets inspected along its journey – knitters do quality checks at the machines, boarders watch out for defects, packagers keep an eye out for irregularities – but it might be the most thorough. Heather gave us the walk through.

Before she even picks up a sock, Heather and the other auditors look over the entire tray of socks, checking that the colors and sizes look right, the weight is good, and other visual cues.

Picking up a sock, they start with a cuff check, watching out for signs of broken needles or latches. From there, they assess the leg for uniformness or tensions issues. Heels and toe seams get special attention to make sure everything was stitched together correctly.

It’s amazing how much Heather can spot without even turning the sock inside out. A small defect she notices on the outside of the sock pushes her to turn socks inside out, looking for the larger issues that small defect can signal.

“Each sock has their own personality,” Heather says, meaning certain defects are more likely in one sock style compared to another. The work done by the entire auditing team helps us make sure we only ship the best socks out the door, socks we can stand behind, socks that Heather loves and uses on her travels, including a recent Alaska trip.

If you’re looking for a sock recommendation, Heather loves the Steely and Mountaineering socks for wintertime. Her new fox tattoo has also made her a fan of the Animal Haus fox socks, cause why not match?

Heather — Packaging Line Supervisor

For the record, this is a different Heather. Equally great. This Heather has been a part of the Darn Tough family for an impressive 24 years. Her coworkers like to remind her that’s almost a quarter of a century.

A hockey fan, fisher, and camper, Heather uses and loves Darn Tough socks, but what keeps her here year after year is the people. “I love the people. We work as a team, and we still have a good time. I just enjoy what I do and seeing everybody every day.” We like seeing her too – her sense of humor is on point.

Carts of socks make their way to Heather’s team after inspection is done with them, with a short pit stop first at Stickering, where the carts pick up packets of unassembled packaging. Heather’s team takes that packaging, grabs a pair of socks, and hand assembles every pair to be purchase-ready. Many people on the team were on the auditing team at one point, making this just one more place someone is checking the sock quality.

Packagers work in teams of two, trading off the tasks of putting the packaging around the socks and placing packaged socks into boxes that can be handed over to shipping. This gives each person a break, important when you consider that a single team packages between 2,000-3,000 pairs per day. AKA up to 250 dozens, cause when you see as many socks as Packaging sees, you start counting in dozens.

Packaged and boxed socks are placed on a skid, then wheeled over to Shipping, the last step in the process of getting Darn Toughs from idea to your door.

Don — Shipping & Receiving Supervisor

A 10-year Darn Toughian, Don has been involved at almost every point of the sock-making process at one point of another, from boarding and wash/dry to knitting and picking orders. He loves seeing the entire process and is always asking how we can do it better, more efficient.

Efficiency is vital for Don. “It’s surprising the volume of socks we process with the number of employees we have.” The team is six people, including himself, six people who get a lot done. They see socks out the door to destinations all around the world.

Once the skids come in from Packaging, shippers do a final quality check to make sure everything is all set, that what’s on the box label is what’s in the box. They also pull out a couple socks from each box to make sure all looks good. Then it’s a matter of getting the right sock boxes onto the right truck and out the door.

That wraps up the sock journey (well, at least for the moment – maybe we’ll take you on a tour through our Warranty Program in a future post). One last Don quote though.

“I’m 42 and I still skateboard. I haven’t broken a bone yet.”

Skate on Don.

P.S. He’s hoping to get a chance to skate in the Mill. We are maybe including that here in hopes it’ll help make that dream a reality. Shh…